Our Manufacturing Department is comprised of three sections: the Manufacturing Section, the Production Management Section, and the Distribution Management Section. By setting the quality guideline that “We always create extremely safe and high quality products based on our sense of responsibility and mission, in order to contribute to people’s happiness,” we manufacture, produce and deliver safe and secure products, in accordance with the Good Manufacturing Practices (GMP) for health foods.

This Section is responsible for manufacturing oyster meat essence by carefully selecting fresh raw oysters harvested in Japan in spring which are a reservoir of nutrition, such as natural minerals and vitamins, extracting nutrition such as trace elements and novel antioxidants from the oyster meat by special manufacturing method for which the company obtained a patent, and concentrating them.

The vacuum concentration method for processing oyster meat is a cutting-edge manufacturing method, for which our company acquired a patent in Japan and the U.S., and our patent application being processed in France and the U.K.

In this section, the tablets of oyster meat essence are packaged in a clean room whose temperature and humidity is controlled and which has pressurized equipment, in accordance with the GMP for health foods. Each product is visually inspected and packaged, and only those products meeting our strict inspection criteria are accepted.

The containers of the tablets are packaged with automatic filling packers. At this time, the expiration dates of the products are printed.

The bottles are automatically and completely sealed with automatic cap fasteners when they are filled with tablets.

Auto-labelers can put a label on the bottles automatically. The expiration dates are printed at the same time. Then, only the products which pass the visual check in the final inspection process are recorded on the record slips and sent to the box packing process.

Bottled products are wrapped with cushioning to prevent breakage during transportation and then neatly placed one by one in the packages.

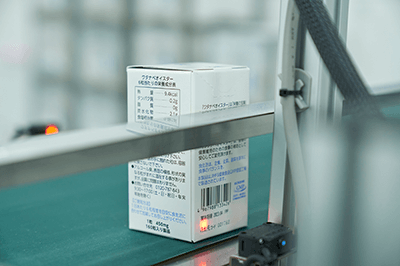

After the final check by visual inspection, the expiration date is printed on the package and sent to the distribution and shipment process.

Products are managed the by the product numbers to prevent mistakes in shipping, and are inspected two more times. The inspected products are manually packed one by one, and shipped to the pharmacies and drugstores across Japan which handle our products.

Products are visually checked

one by one.

We strive to neatly wrap products, as we ship only articles which conform to standards.

All products have client code numbers.